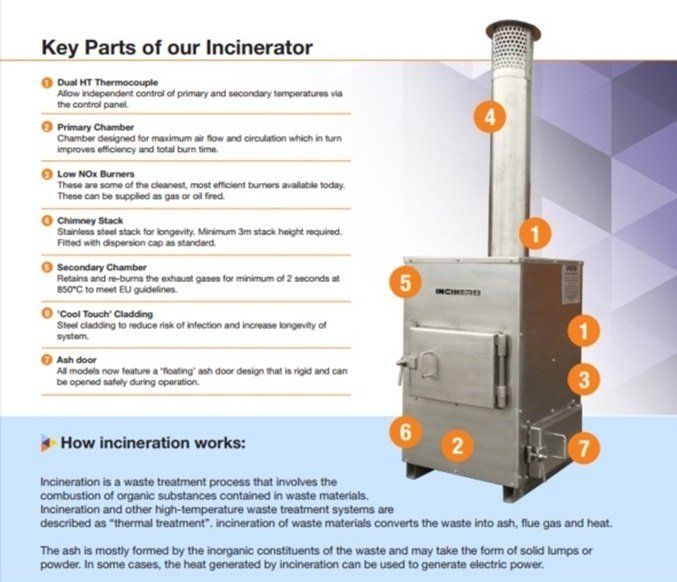

First Philippine Medical Incinerator - i8-M15

This Model is a small nfootprint, plug and play medical incinerator. Developed for use is smaller health clinics, laboratories and regional hospitals. It is well suited for use as a mobile incinerator due to its small footprint and simple setup.

Plug ‘n’ Play Setup & Operation

Simply remove from packaging, connect electricity and add some fuel to the tank- Making this an ideal model to have trailer mounted so you can relocate your incinerator to where it is needed most week by week.

Industry Leading Insulation

Coretex insulation is a specifically formulated substrate containing various levels of material that ensure almost all of the heat generated within our incinerators stay inside them - increasing performance and efficiency to another level..

Long Last Construction

The i8-M15 internal frame is constructed from British made high quality 3mm mild steel plate. They are fully welded for maximum strength by our time- served coded welders and now fully clad in steel. Meaning you get years of trouble-free operation.

Designed to excel

Each of our incinerators has been tested to exacting standards ensuring they meet our strict guidelines.

This machine can reach in excess of 850°C in the secondary chamber and also retains the gases for the 2 seconds required.

Designed to burn Type I - IV pathological waste and infectious and contaminated “red bag,” surgical dressings, plastic test devices and other wastes

Challenge

If you are paying a high fee to haul these waste materials to a disposal site, now is the time to consider the on- site Incineration alternative. On-site incineration is a thorough, fast, and cost effective way to dispose of waste. Our various models are engineered to meet strict air emission regulations without offensive smoke or odour.

- Cladded for heat retention, cool touch & hygiene control

- Rapid, complete and efficient medical waste disposal -

- Patented safety handle for easy access to chamber -

- High quality refractory lining and insulation

- Easy to use CE2 control panel

- Programmable temperature control for complete combustion Secondary chamber* with 2 second retention time

- Fast pre-heat and continual high temperature performance

- Low energy consumption levels

* Our primary combustion chambers are constructed from high grade steel and monolithic refractory lining with a unique concave design to prevent cold spots. The design ensures a natural secondary burn characteristic as when the burner is switched on a flame curtain is created, this ensures the thermal breakdown of smoke/emissions, where in many instances emissions will exit through the stack and into the atmosphere in the form of clean vapor.

.

Value and Safety

All our incinerators’ chambers are lined with high grade refractory concrete rated to 1600°C. Our secondary chamber technology prevents dioxins from cracking into smaller but more reactive molecules, this is known as de novo formation.

This can be especially apparent in the presence of heavy metals, which can act as a catalyst.

The prevention method can be explained as follows: system design forces the micro particulates to pass through a flame curtain, this burns harmful emissions, gas remnants are then retained in the secondary chamber, through thermal decomposition, and complex, controlled air distribution to ensure a clean odourless emission.